|

Repairing small holes and dents in drywall is a relatively straightforward process that can be done with a few basic tools and materials. Here's a step-by-step guide to help you:

0 Comments

Achieving a smooth finish on drywall requires proper sanding techniques. Here are some steps to follow for sanding drywall:

Taping and mudding drywall are critical steps in achieving a smooth and seamless finish for walls and ceilings. Here are some best practices to follow for taping and mudding drywall:

Measuring and cutting drywall sheets requires careful planning and precision to ensure accurate results. Here's a step-by-step guide to help you measure and cut drywall sheets effectively:

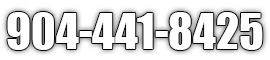

By following these steps, you should be able to measure and cut drywall sheets accurately for your project. Jacksonville drywall made this post happen. Hanging drywall on ceilings can be a challenging task, but with the right approach and some helpful tips, you can achieve a professional-looking result. Here are some tips for hanging drywall on ceilings:

When it comes to choosing the right drywall for your project, several types are available, each with its own specific characteristics. Here are some common types of drywall and their typical uses to help you make an informed decision:

Drywall is a popular material used for interior walls and ceilings in homes and buildings. While it is relatively durable, it can develop certain problems over time. Here are some common drywall problems and suggestions on how to fix them:

When it comes to drywall, there are several different types available, each with its own characteristics and suitable applications. Understanding the different drywall types can help you choose the most appropriate one for your specific needs. Here are some common types of drywall:

Drywall is a common building material used for interior walls and ceilings. While it is durable, it can develop certain issues over time. Here are some common drywall problems and suggested solutions for fixing them:

|

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2023

Categories |